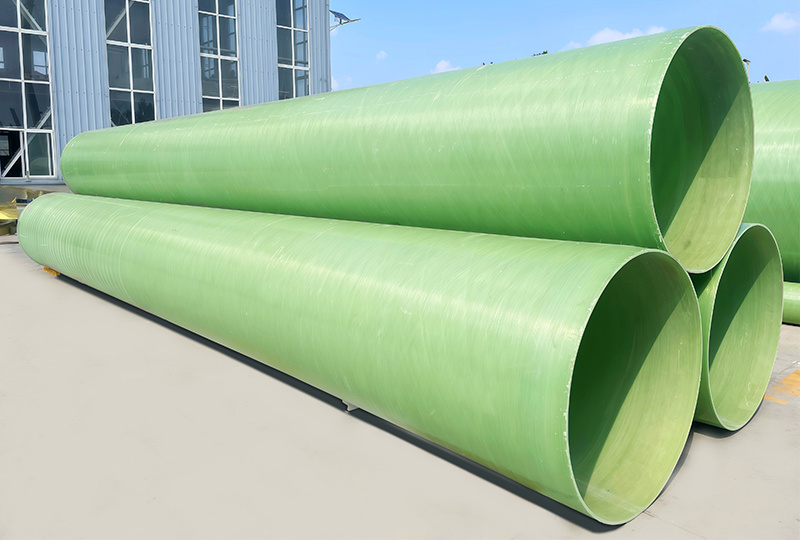

Large FRP tanks: A powerful assistant for storage in the chemical industry

In the chemical industry, various acidic and alkaline liquids or gases are frequently handled during production. These substances are highly corrosive, placing extremely high demands on storage equipment. Large FRP reinforced plastic (FRP) tanks have emerged as a result, becoming the "guardians" of the chemical industry.

Large FRP tanks are made by precisely winding resin and glass fibers using sophisticated machinery. This unique manufacturing process gives it many advantages. Its corrosion resistance is extremely strong. In environments with frequent contact with chemicals, it can effectively resist the corrosion of acids and alkalis, greatly extending the service life of the equipment. For example, a certain chemical company previously used traditional metal storage tanks to store liquids from pickling tanks and neutralization pools. Due to the ease with which metals corrode, the storage tanks frequently leaked, affecting not only production progress but also causing environmental pollution and resource waste. Later, the company switched to large FRP tanks. After a period of use, the tanks showed no signs of corrosion, production proceeded smoothly, and the repair and replacement costs caused by equipment damage were reduced.

In addition to corrosion resistance, large FRP tanks also have the characteristic of high strength. When subjected to heavy pressure and impact, it can still maintain the integrity of its structure, ensuring the safety of stored materials. In chemical production, some unexpected situations may be encountered, such as equipment collisions and material impacts. Large FRP tanks can effectively resist these external forces due to their high strength characteristics, preventing ruptures or leaks.

Furthermore, large FRP tanks have a long service life, reducing the cost of frequent replacement and maintenance compared to traditional metal materials. Moreover, it can be flexibly designed to meet the needs of different industries and various complex process requirements. Its highly automated manufacturing process ensures product quality consistency and production efficiency. With technological advances and increasing environmental awareness, the application prospects of large FRP tanks in the chemical industry will become even broader.

Next

Related Articles

Several Types of Fiber Filament Winding Processes

Related Products