Filament winding

Filament winding is a widely used method in composite material manufacturing, characterized by the following main features:

① The products exhibit high specific strength. Compared to other molding processes, filament winding enables fibers to be arranged neatly and precisely along the predetermined direction, thereby fully leveraging the strength potential of the fibers and achieving high specific strength and specific stiffness. For example, the specific strength of common glass fiber-reinforced composites can be three times that of steel and four times that of titanium.

② It facilitates the realization of uniform strength structural design. During the winding process, the fiber placement direction, number of layers, and quantity can be flexibly adjusted according to the stress conditions of the component, thereby achieving a rational uniform strength design and optimizing the structure.

③ With low production costs and good quality consistency, the filament winding process typically uses continuous fibers, roving, or non-weft tapes as reinforcing materials, eliminating the need for textile processes. This not only shortens the production workflow and reduces costs but also avoids stress concentration caused by fabric weave points and chopped fiber ends. The process is easy to mechanize and automate, ensuring stable product quality and making it suitable for mass production.

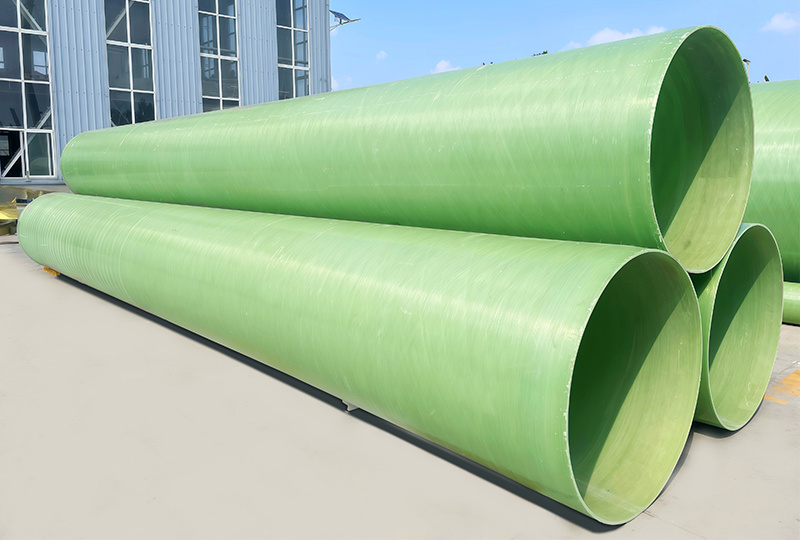

④ It is particularly well-suited for manufacturing corrosion-resistant pipelines, storage tanks, high-pressure pipelines, and containers, offering unique advantages in these areas that are difficult to replicate with other processes.

Despite the significant advantages of filament winding technology, it also has certain application limitations:

① During the winding process (particularly in wet winding), bubbles tend to form, leading to increased porosity within the product. This, in turn, reduces interlaminar shear strength, compressive strength, and stability resistance. To mitigate bubbles and porosity, production often requires the use of highly active diluents, adjustment of resin viscosity, enhancement of fiber wettability, and appropriate increase in fiber tension.

② Openings in the product can easily cause stress concentration around the edges and reduce interlaminar shear strength. Machining processes such as cutting, drilling, or grooving for assembly purposes can also compromise the overall strength of the wound structure. Therefore, destructive processing after full curing should be avoided in structural design whenever possible. If openings or grooves are necessary, local reinforcement measures should be implemented.

③ This process has relatively poor adaptability to components with concave surfaces, imposing certain limitations on product shapes. Currently, filament winding technology is primarily suitable for positive-curvature rotational bodies such as cylinders and spheres. For non-rotational bodies or negative-curvature rotational bodies, the winding principles and equipment development remain considerably complex and are still in the exploratory research stage.

Next:

Related Articles

Several Types of Fiber Filament Winding Processes

Related Products

Content updating……