Manufacturing process and performance characteristics of large FRP reinforced plastic tanks

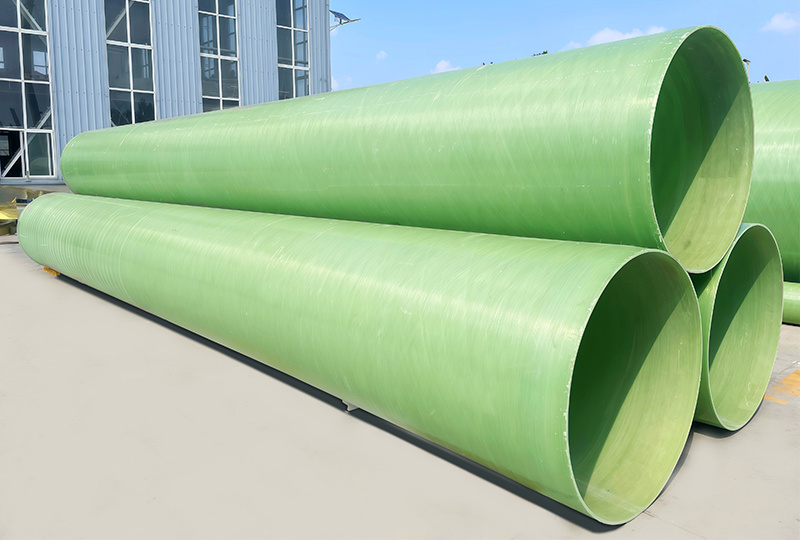

The manufacturing process of large FRP tanks mainly adopts precision machine winding technology. Resin and FRP are wound in a certain proportion and order by a precision machine to form the main body structure of the tank. During the winding process, the amount of resin and FRP and the winding method can be adjusted according to different needs to achieve different performance requirements of the tank.

This manufacturing process gives large FRP tanks many performance characteristics. First is corrosion resistance. FRP tanks are made of high-quality FRP reinforced plastics, with a smooth and durable surface. This material is not easy to rust and is not corroded by chemicals. It is especially suitable for storing various chemical liquids and gases. In harsh industrial environments, such as chemical production workshops, where acids and alkalis are everywhere, FRP tanks can effectively resist the erosion of these substances and ensure the safety of stored substances.

Secondly, it has high strength characteristics. FRP is like a group of super powerful "thin thread warriors", and resin is the "adhesive elf" that tightly unites these "warriors". Their strong combination creates an incredibly strong FRP tank body. When subjected to heavy pressure and impact, the FRP tank can still maintain the integrity of its structure, providing a stable storage environment for the stored substances.

In addition, large FRP tanks also have advantages such as long service life, strong design capabilities, strong processability, and environmental protection. Compared with traditional metal materials, it has a longer service life, reducing the cost of frequent replacement and maintenance. According to the needs of different industries, it can be flexibly designed to meet various complex process requirements. Its manufacturing process is highly automated, ensuring product quality consistency and production efficiency. Moreover, the design flexibility and long service life of FRP tanks reduce resource waste and comply with the sustainable development concept of modern industry.

Related Articles

Several Types of Fiber Filament Winding Processes

Related Products